The Air Angle Grinder generally provides superior torque compared to electric models due to the design of its pneumatic motor. Pneumatic tools are powered by compressed air, which allows them to produce significantly higher torque-to-weight ratios. This means that for the same size and weight, an Air Angle Grinder can generate more torque, enabling it to perform better in demanding grinding tasks. In heavy-duty grinding applications, this higher torque allows the tool to efficiently handle tough materials like steel, concrete, and other industrial-grade substances, making it the preferred choice for jobs that require aggressive material removal.

One of the standout features of the Air Angle Grinder is its ability to deliver consistent power output throughout its operation. Unlike electric grinders, which may experience power dips due to battery depletion or voltage fluctuations, the pneumatic system of an Air Angle Grinder ensures that the tool receives a steady flow of compressed air, thus maintaining a uniform power level. This consistent performance is especially valuable during long, continuous grinding sessions, where interruptions in power delivery can affect productivity and the quality of the work being performed. The ability to operate without pauses for battery charging or power loss is a significant advantage when working on large-scale industrial projects.

The Air Angle Grinder is inherently less prone to overheating compared to electric models. Pneumatic tools are designed to dissipate heat through the exhaust air, ensuring that they can run for extended periods without risking thermal overload. On the other hand, electric grinders can overheat when used for prolonged heavy-duty applications, especially in environments where air circulation is limited or the tool is not given enough time to cool down. Overheating can lead to a drop in performance or, in extreme cases, damage to the electric motor. This makes the Air Angle Grinder particularly well-suited for continuous operations in high-demand industrial environments, where reliable performance without downtime is essential.

The Air Angle Grinder is specifically designed to handle high-powered grinding tasks, including the removal of tough materials such as thick steel plates, rust, welds, and concrete. The high torque and consistent air-powered performance allow it to perform efficiently across a wide range of heavy-duty applications. Whether it's grinding, cutting, polishing, or sanding, the Air Angle Grinder can tackle these tasks with more force and reliability compared to electric grinders, which may struggle with similar workloads, especially when it comes to tougher materials. The tool’s ability to maintain power under load ensures that users can rely on it to get the job done quickly and effectively, even in the most challenging work environments.

Another significant advantage of the Air Angle Grinder over electric models is its freedom from the limitations of power cords or battery life. Pneumatic tools are powered by an external air compressor, which means they are not restricted by cord length or the need for frequent battery changes or recharges. This provides greater mobility and flexibility in heavy-duty applications, especially when working in large areas, on scaffolding, or in confined spaces. Electric grinders, by contrast, can be cumbersome due to the need for power cords or the potential inconvenience of running out of battery power, which may require users to stop working and recharge or swap out batteries. With an Air Angle Grinder, users have the flexibility to move freely around the workspace, enhancing efficiency and reducing downtime.

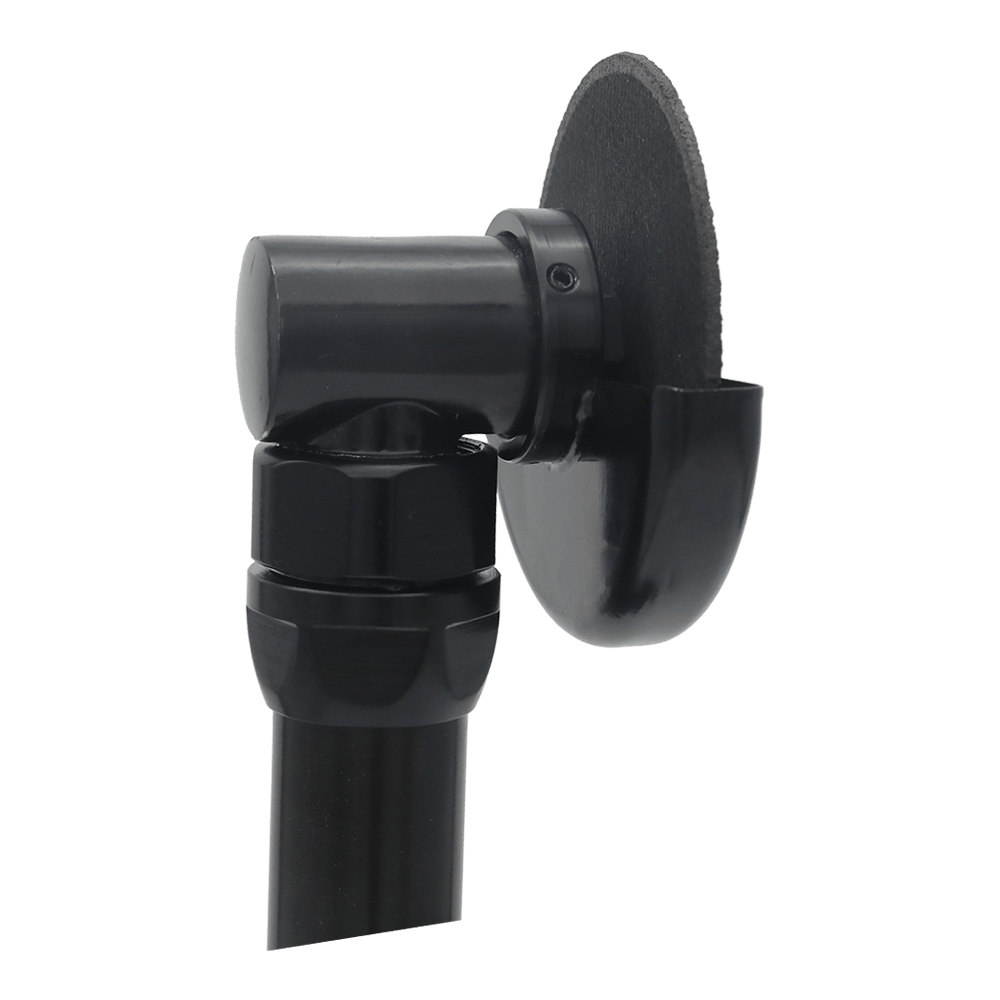

Despite offering high torque and power, Air Angle Grinders are often more compact and lightweight compared to electric models. This is due to the efficiency of the pneumatic motor and the absence of heavy batteries or electric motors. The compactness and lighter weight of these grinders make them highly maneuverable, allowing users to work in tight spaces or at angles that may be challenging for larger, heavier electric models. This is particularly advantageous for workers performing overhead tasks or grinding in confined areas where mobility is key. The lighter weight reduces the amount of physical strain on the user, contributing to better ergonomics and comfort, especially during extended use.

English

English 中文简体

中文简体 русский

русский Deutsch

Deutsch Português

Português Español

Español